Studying the Effect of Magnetron Copper Deposition on the Surface Topography of Biodegradable Antibacterial Coating

-

Bauyrzhan , Maratuly

East Kazakhstan Technical University, Competence center «Smart engineering», Oskemen, Kazakhstan , Tel: +77 775853178; E-mail: makebake9301@gmail.com

Bauyrzhan , Maratuly

East Kazakhstan Technical University, Competence center «Smart engineering», Oskemen, Kazakhstan , Tel: +77 775853178; E-mail: makebake9301@gmail.com

-

Nurlanovich Azamatov, Bagdat

-

School of Digital Technologies and Artificial Intelligence, D. Serikbayev East Kazakhstan Technical University, Ust-Kamenogorsk, 070010, Kazakhstan

Abstract: Background: The surface properties of the materials used significantly influence the success and longevity of medical implants. Increasing surface roughness promotes osteoblast activity and osseointegration, while biodegradable materials such as copper have shown potential for antimicrobial applications. However, the effect of coating parameters on surface topography is not well investigated.

Methods: Sputtering of copper was performed using EPOS-PVD-440 system (Zelenograd, Russia). The samples were examined by Scanning Electron Microscopy (SEM) with subsequent image processing in Mountains software (Digital Surf). Antibacterial efficacy was evaluated against Staphylococcus aureus by measuring the zone of inhibition. Additionally, copper ion release was monitored over time to assess its correlation with changes in surface topography.

Results: Higher sputtering currents increased surface roughness and particle size, with a significant release of copper ions within the first 24 hr of immersion. Samples sputtered at higher currents exhibited coarser grain structures. The release of copper ions in the simulated biological environment led to further changes in surface topography, highlighting the critical influence of sputtering parameters on coating properties.

Conclusion: Optimizing magnetron copper deposition parameters enhances the surface topography and antibacterial effectiveness of biodegradable coatings on implants.

Introduction :

It is widely acknowledged that the quality and quantity of bone tissue, along with the establishment of sufficient primary stability during implant placement and the formation of direct contact between bone and implant, are critical parameters that influence the overall success and survival of implants 1. However, the optimal combination of various surface modifications for achieving a more predictable outcome remains unclear. Studies indicate that enhancing the surface roughness of implants promotes osteoblast proliferation, collagen synthesis, and integrin expression in the extracellular matrix, thereby enhancing the mechanisms associated with osseointegration 2.

The retention of osteogenic cells on implant surfaces plays a pivotal role in facilitating osseointegration 3. The surface properties of biomaterials determine the processes associated with the biological reaction. Micro-rough surfaces (roughness below 50 μm) are easily prepared and practical to detect. In terms of biocompatibility, micro-roughened surfaces, compared to smooth surfaces, exhibit earlier adhesion of mineral ions or atoms, biomolecules, and cells. They also promote stronger fixation of bone or connective tissue, resulting in a thinner tissue reaction layer with reduced or absent inflammatory cells. Additionally, micro-rough surfaces help prevent microbial adhesion and plaque accumulation. Consequently, implants featuring micro-roughened surfaces hold promising potential for widespread use in the future 4.

Nevertheless, the surface topography of implants undergoes changes not only after mechanical processing but also after coating. Addressing the issue of bacterial growth on implant surfaces, researchers have explored alternative surface modification options, including the application of copper coatings. Copper, being a biodegradable material, has shown potential for antimicrobial use in the medical field 5.

In recent times, copper coatings have garnered significant attention for their antimicrobial applications in medicine. As copper is a biodegradable material, the final surface topography is determined by what remains after the release of the copper coating. Implants with copper spray coatings undergo two stages of surface topography formation. The first occurs during sputtering, while the second occurs during implant healing and the subsequent release of copper ions. For coatings thinner than 10 µm, the topography may exhibit shapes similar to those of the substrate 6. Caio et al observed that the coating's topography is derived from that of the substrate surface, with the latter being influenced by pre-machining 7. Various methods can be employed to modify the implant surface, including vapor deposition, sol-gel processes, electrical discharge coating, plasma deposition, laser procedures, electrochemical approaches, and more 8.

The utilization of magnetron atomization systems for coating finds a broad spectrum of applications 9. Achieving the desired properties of coatings with magnetron atomization systems necessitates careful consideration of the methods for calculating their technological and design parameters. The complexity arises from the use of inhomogeneous crossed electric and magnetic fields in magnetron atomizing systems, where the electrical parameters of the discharge are significantly influenced by operating pressure, the magnitude and configuration of the magnetic field, and the design intricacies of the atomizing system. All of these factors contribute to the challenge of accurately analyzing the phenomena occurring in the discharge of a magnetron system.

One of the parameters exerting the most significant influence on surface roughness is the current strength. In a study by Chinsakolthanakorn et al, it was discovered that at the highest atomization current, not only did the roughness increase, but also the average thickness of the coatings 10. The crystal structure, surface morphology, microstructure, and elemental composition exhibit strong dependence on the sputtering current. Peaks observed for coatings deposited at a current greater than 50 mA indicate the presence of a more crystalline phase 11. Another factor capable of influencing the properties of the resulting coating is the deposition temperature 12.

The substrate voltage primarily influences the bombardment energy of atomized particles. Low-energy particles can significantly contribute to grain growth by enhancing the surface mobility of adatoms upon collision without penetrating beneath the surface 13. When subjected to a negative substrate voltage, charged particles accelerate towards the substrate surface, resulting in an increased energy of incident particles bombarding the substrate. Consequently, a more negative substrate voltage leads to higher particle bombardment energy. Furthermore, the diffusion ability of particles with high bombardment energy deposited on the substrate is enhanced.

As a result, applying an appropriate negative voltage to the substrate can increase the crystallinity of the coating and potentially reduce lattice defects. However, excessively high negative voltages may have adverse effects, as high-energy bombardment particles could deteriorate the crystalline structure of the coating on the substrate, leading to re-sputtering and an increase in lattice defects 14.

As evident from prior studies, the efficiency of the magnetron sputtering system relies on the accurate selection of operating parameters, and the stability of these parameters dictates the consistency of the coating deposition rate and the reproducibility of resulting coating properties. Maintaining the required rate of coating deposition in the magnetron system with sufficient accuracy is achievable through the stability of crucial parameters, such as discharge current or power supply.

The objective of this study is to ascertain the correlation between implant roughness and the parameters of the magnetron system. Additionally, the research aims to delineate the stages of surface topography formation both during sputtering and after the release of ions from the biodegradable coating.

Materials and Methods :

Samples, with a diameter of 10 mm and a thickness of 2 mm, were precision-cut using a Computer Numerical Control (CNC) machine, specifically the CTX 510 ecoline (DMG MORI AG, Germany), from the titanium alloy Ti-6Al-4V (GOST 26492-85, equivalent to grade 5, DOT, Rostock, Germany). Before magnetron sputtering, the samples underwent a 30-min cleaning process in distilled water using a Stegler 22DT ultrasonic bath (Shenzhen Bestman Instrument Co., Ltd., China). Subsequently, they were air-dried for 40-60 min.

Magnetron sputtering was performed using an EPOS-PVD-440 system (Zelenograd, Russia) 15. A pure copper target (99.99%) was employed as the coating material. The magnetron sputtering parameters were as follows: argon served as the working gas at a flow rate of 62 ml/min, the base pressure in the chamber was 1.9×10-3 mbar, and the working pressure was 2×10-3 mbar. The distance between the copper target and the titanium substrate was maintained at 150 mm. The discharge voltage was set to 310 V. The discharge current strengths were 1 A and 2 A, with each applied for 30 min in the first series of samples. The copper sputtering times were 60 and 120 min, corresponding to a current strength of 1 A in the second series of samples.

The study employed optical microscopy and Scanning Electron Microscopy (SEM) techniques to examine the surface morphology of copper coatings. The acquired images underwent processing using Mountains software (Digital Surf) 16, which featured a particle analysis function capable of filtering out particles larger than 2 μm2. The surface roughness was visualized using a 3D view function.

SEM is a crucial technique for observing various surface structure characteristics and enables the visualization of details as small as 10 nm 17. It can be synergistically combined with other techniques, such as Mountains software, to enhance the scope of information obtained.

The assessment of roughness after copper release was performed on samples from the second series with a discharge current of 2 A. Roughness measurements were taken before and after plating using a Micron-beta non-contact interference 3D profilograph. To induce changes in surface topography, the samples were immersed in a physiological saline solution. The samples remained in the saline solution until the release of copper reached minimal levels, determined by measurement with an Agilent 7500cx ICP-MS inductively coupled plasma mass spectrometer (Agilent Technologies, USA). Following the release of copper ions, the samples were re-evaluated using the profilometer.

Bacterial cultures of Staphylococcus aureus (S. aureus) (Gram-positive), with a titer of 9.1×1010 Colony-Forming Units (CFU)/ml after culturing for 14 hr at +30±1°C in liquid nutrient broth stirred at 150 rpm, were utilized for in vitro studies on the antibacterial properties of the coatings and the uncoated titanium alloy surface. A biologically neutral Polypropylene (PP) disk served as the control. The samples were sterilized under a UV lamp before the experiment. The optical density of the cultures grown overnight was measured at 600 nm (OD600), yielding a value of -0.47 units. The prepared bacterial suspension (with optical density OD 0.47) was plated on Petri dishes with nutrient agar, forming a 5 mm thick layer. Disks of the tested materials were placed on the agar and incubated for 24 hr at +37±1°C. The antibacterial activity of the samples against S. aureus strains was determined after 24 hr by measuring the growth suppression zone of the test cultures in millimeters (mm). The results represent the average value of four independent series of measurements (with differences between them less than 2-3%).

Results an Discussion :

The surface morphology of coatings can be notably influenced by the applied current strength during the process. As illustrated in figure 1, an increased current strength led to coatings with more prominent surface characteristics, whereas lower current strength resulted in smoother surfaces. Consequently, regulating current intensity proves to be a valuable tool for manipulating the surface characteristics of sputtered coatings. It is essential to acknowledge, however, that other factors, including sputtering time, may also contribute to shaping the surface morphology.

Extended sputtering times can contribute to minimizing irregularities in sprayed coatings. Samples subjected to a one-hour spraying process exhibited surface roughness, suggesting potential non-uniformity in the coating. Conversely, when the sputtering time exceeded one hour, there was a reduction in the depth of irregularities. These findings imply that prolonged spray times facilitate the settling and leveling of the coating, leading to a smoother and more uniform surface.

By varying the duration of sputtering, we were able to assess the impact of layer-by-layer sputtering on surface smoothing. Experimental data indicate that samples subjected to longer spray times exhibited a roughness approximately 1.5 times lower than samples sprayed for only 1 hr (Figure 1). In contrast, samples sprayed for just 0.5 hr displayed relatively higher roughness. This implies a more pronounced leveling effect during the initial spraying phase, with the coatings becoming flatter at a diminishing rate as the spraying continues. These results offer insights that can be applied to optimize the spraying process for achieving specific surface properties and characteristics.

A formula has been formulated to articulate the relationship between coating roughness and spraying time, providing a valuable tool for predicting roughness under various spraying conditions. According to the derived formula, it is evident that coating roughness diminishes with prolonged sputtering time, with the most significant reduction occurring during the initial stage of sputtering. These observations affirm the significance of optimizing the spraying duration to attain the intended surface characteristics and optimize coating performance. The correlation between roughness and spraying time is expressed by the following formula:

R=R0-C×tα

where R represents the coating roughness at time t, R₀ is the initial roughness, C is a constant coefficient, and α is the exponent in the power-law relationship between roughness and time. Calculations indicate that α typically falls within the range of 0.5 to 0.8 for the sputtering process, signifying a trend where roughness decreases with increasing time, yet the rate of decrease slows down as time progresses. This formula proves instrumental in predicting the roughness of coatings under diverse sputtering conditions, offering valuable insights for optimizing the sputtering proces s to attain the desired surface properties and characteristics.

The current strength employed during sputtering plays a crucial role in shaping the surface morphology of coatings. Elevating the current strength to 2 A enhances nucleation intensity, potentially giving rise to the re-evaporation of nucleates during deposition. A systematic analysis of the samples through inverse images and a characterization table demonstrates that augmenting current intensity results in a proportional increase in the average size of bulges on the coating surface. The presented data unequivocally emphasize the importance of optimizing the sputtering current to attain the intended surface characteristics and optimize coating performance.

The higher boiling point of copper, at 2562°C, necessitates increased energy for nucleation during sputtering. The heightened nucleation observed at 2 A current can be attributed to this elevated energy requirement. However, it introduces the risk of re-evaporation of nucleates during deposition, potentially impacting the final coating's quality. Examination of the samples through the characterization table confirms that an increase in current strength corresponds to a rise in the average size of bulges on the coating surface. These observations underscore the critical importance of optimizing current strength during sputtering to achieve the desired surface morphology and coating performance.

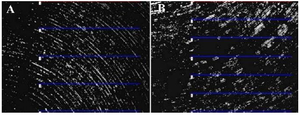

SEM images vividly illustrate the variation in surface morphology among coatings at different current strengths (Figure 2). The analysis reveals that increasing the current strength to 2 A results in a 16% upsurge in the number of particles compared to 1 A sputtering, while the average particle size is approximately half (539.9 nm²/275 nm²=1.96). Coatings sputtered at 2 A exhibit a coarser grain structure in comparison to those sputtered at 1 A. The current-dependent nature of surface properties underscores the significance of choosing an appropriate current strength to achieve the intended surface morphology and characteristics.

The topography of the implant surface undergoes three distinct stages of change: before sputtering, after sputtering, and following implantation in the human body. Biodegradable coatings on implants may naturally develop roughness after insertion into the patient's body, primarily due to the release of copper ions from the coating. This third stage of implant surface topography formation takes place within a biological environment, where the implant is surrounded by human tissues and fluids. In our research, we replicated the conditions of the human body environment using a NaCl solution to observe the impact of copper release on the implant surface.

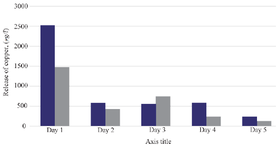

The mass spectrometric measurements of copper ion release (μg/L) from copper coatings into the physiological solution medium at 1, 2, 3, 4, and 5 days post-immersion are presented in figure 3. As depicted in figure 3, the quantity of released Cu ions after 1 day of immersion in the physiological solution is approximately 2525.3 μg/L for the thick film and about 1477.2 μg/L for the thin film. However, by the end of the fourth day, there is a significant decrease in the released Cu ions for both films, measuring 235.2 μg/L for the thin film and 584.4 μg/L for the thick film. This suggests a direct correlation between the amount of released copper ions and the thickness of the coating. Importantly, it indicates that the majority of copper ions are released during the initial 24 hr of contact with the physiological solution.

The topography of the implant surface is influenced by the surrounding biological environment. Notably, immersion of the implant specimens in a NaCl solution was observed to cause specimen splitting. Two roughness measurements were obtained to compare the implant surface roughness (Figure 4). It's important to note that the average roughness of the samples after sputtering is smaller than the roughness before sputtering 18. This observation suggests that the sputtering process can effectively reduce the roughness of the implant surface, resulting in a smoother surface. However, the suitability of the surface for implantation depends on factors beyond surface roughness. The release of copper ions from the biodegradable coating in the human body environment may elevate the surface roughness of the implant, necessitating consideration of the impact of the biological environment on implant topography.

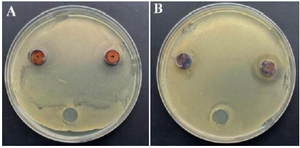

The findings of this study highlight the substantial impact of coating modes on the topography and surface roughness of coatings, subsequently influencing the interaction between the coating and surrounding biological tissue. Coatings subjected to shorter sputtering durations exhibited a notably rougher surface compared to those with longer durations, potentially influencing cell attachment and protein adsorption. Nevertheless, it is noteworthy that all coatings continued to undergo topographical modifications upon the release of copper ions. The zone of inhibition averaged 17.5 mm, with maximum observed values of 18 mm. This confirms the antibacterial properties of copper coatings against S. aureus bacterial strains, providing evidence of the antibacterial efficacy of copper. In figure 5, the growth of bacterial test strains on copper-coated metal disks is depicted, along with images of a control PP disk.

Conclusion :

Control of sputtering conditions proves to be crucial in achieving the desired surface topographies and coating characteristics during sputtering processes. The surface morphology of coatings is significantly influenced by the current strength and deposition time, wherein longer deposition times and lower current strength contribute to smoother and more uniform surfaces. Moreover, the present study provides a formula for predicting coating roughness under diverse deposition conditions. These results hold promise for enhancing the performance of coatings across various applications, from medical devices to electronic components and beyond. Future studies should further explore the impact of additional deposition factors on the surface morphology of coatings.

Acknowledgement :

This research was supported by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan, grant number AP14871715.

Conflict of Interest :

All authors declared that there is no conflict of interest.

Figure 1. Dependence of roughness on spraying time: A) 0.5 hr (Ra=0.8943); B) 1 hr (Ra=0.5786); c) 2 hr Ra=0.4185.

|

Figure 2. Particle analysis of SEM images with exclusion of particles less than 0.2 μm: A) sputtering at current intensity of 1 A; B) sputtering at current intensity of 2 A.

|

Figure 3. Depicts the concentration (µg/L) of copper ions released into a 0.9% NaCl solution from copper films of varying thicknesses.

|

Figure 4. Average roughness of samples (A) before sputtering (1.277 μm); (B) after copper extraction (2.249 μm).

|

Figure 5. The growth of bacterial test strains on metal disks: sputtering time A) 2 hr; B) 0,5 hr.

|

|